Factory making Frozen Food Production Line - Full automatic professional fish feed extruder fish feed pelletizing machine – Dongxuya

Factory making Frozen Food Production Line - Full automatic professional fish feed extruder fish feed pelletizing machine – Dongxuya Detail:

Brief introduction

1.Fish feed pelletizing machine Description

Fish feed pelletizing machineis used to produce different kinds of pet food , floating fish feed. Fish feed pelletizing machine works with simple operation,accurate parameter control.

The products can be finished in the stipulated temperature,pressure,humidity and time. Owing to the reasonable design,special materials ,the staility , repairs can be guaranteed and ensured. The various shape and taste must meet the different requirements of pet food.

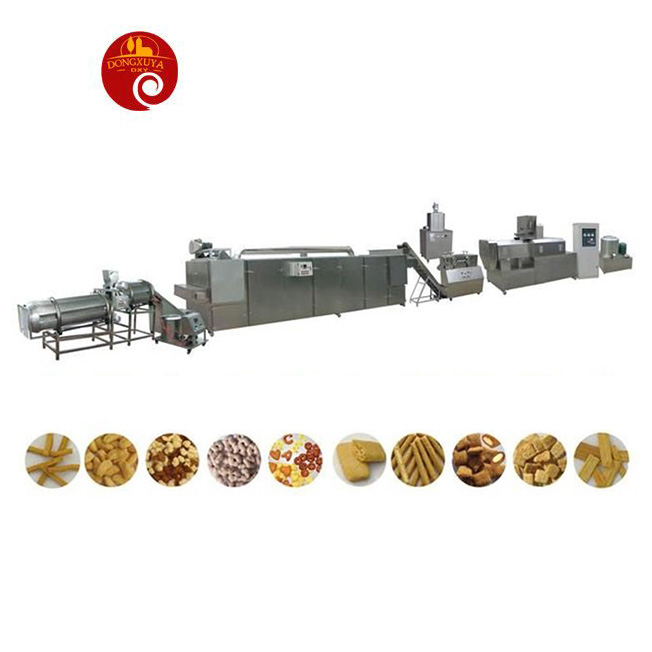

2.The whole processing line of fish feed pelletizing machine

Mixer – Screw conveyor – Twin screw extruder – Air conveyor – Dryer – Flavoring line.

3.Voltage of fish feed pelletizing machine

Three phases:380V/50Hz,single phase: 220V/50Hz,we can make it according to customers` local voltage according to different countries.

4.Raw material of fish feed pelletizing machine

Fish feed pelletizing machine adopts corn powder,rice powder,wheat flour,meat etc as main materials.

5.Capacity of fish feed pelletizing machine

We can produce fish feed pelletizing machine with different capacity which is from 100 kg/h to 3500 kg per hour. The popular capacity floating fish feed extruderare 100-150 kg per hour, 200-260kg per hour,400-500 kg per hour, 800-1000kg per hour.

6.Twin screw extruder (Full automatic professional fish feed extruder)

6.1 Twin screw extruder adopts frequency speed controlling with high automation.

6.2 The screws are made of the stainless steel and special craft,which has the advantage of durable usage,high pressure,and longer life.

6.3 The forced lubrication system,which can guarantee the equipment transmission life longer.

6.4 Auto-temperature control system and self-cleaning,which makes it more convenient.

6.5 It has the widest range of applications and can produce different products with different equipmetn and models.

7.Full automatic professional fish feed extruder packaging and delivery

1.Daub coal oil on the surface of the machines.

2.Plastic film as the inner packing.

3.Standard export wooden case as the outer packing.

4.Ship,Train or depend on clients` requirement.

Product detail pictures:

Related Product Guide:

We constantly carry out our spirit of ''Innovation bringing advancement, Highly-quality guaranteeing subsistence, Administration selling advantage, Credit rating attracting buyers for Factory making Frozen Food Production Line - Full automatic professional fish feed extruder fish feed pelletizing machine – Dongxuya , The product will supply to all over the world, such as: Jamaica, Plymouth, Nigeria, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.