Special Design for Energy Bar Extruder - Industrial Automatic Corn Flakes Extruder Corn flakes making Machine Price – Dongxuya

Special Design for Energy Bar Extruder - Industrial Automatic Corn Flakes Extruder Corn flakes making Machine Price – Dongxuya Detail:

Brief introduction

1. Description of corn flakes processing line:

Corn flakes processing line is a fully automatic line to solve the sticky material on the roller, low output of flakes pressing, low shaping rate, poor taste and so on. Reasonable equipment collocation and realizable process control ensure high quality and delicious corn flakes production.

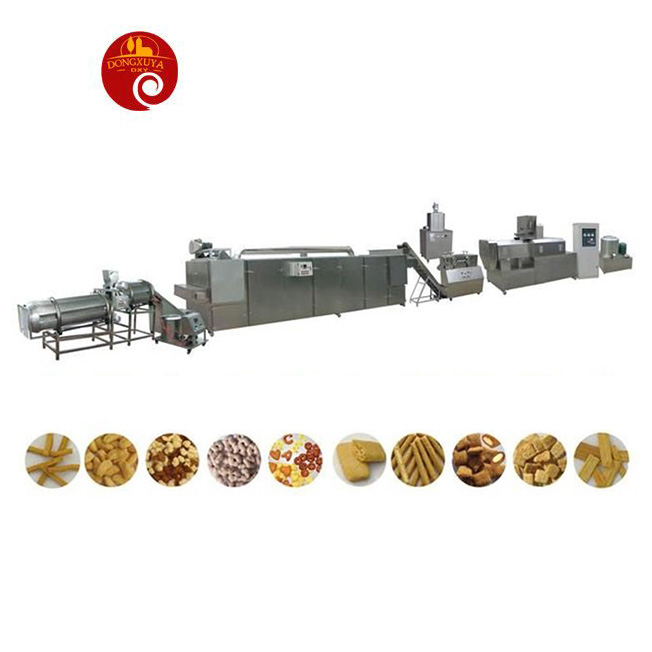

Corn flakes processing line can make corn flakes, coco rings, grain balls, corn stars and various shapes of breakfast cereals.corn flakes processing line is not only service as breakfast cereal mixed with milk or coffee, but also a kind of leisure snacks. The other shapes of cereals such as rings, balls, chocks, curls etc. are available by this corn flakes processing line.

2.Raw materials of corn flakes processing line:

Adopts corn flour, wheat flour, rice flour and other grains flour etc as raw materials

3.Capacity of corn flakes processing line:

100-150 kg/h, 200-250 kg/h, 350-500 kg/h

4. Flow chart of corn flakes processing line:

Mixing system—Extrusion system—-Drying system—-Flavoring system–Packing system

5.Voltage in China of corn flakes processing line:

Three phases: 380V 50HZ, Single phase: 220V 50HZ, we can make it according to customers’ Local voltage according to different countries

6. Twin screw extruder`s advantage place

1.The main extruder of corn flakes processing line adopts frequency speed controlling with high automation.

2.The screws of corn flakes processing line are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system corn flakes processing line(the extruder) ,which can guarantee the equipment transmission life longer.

4. corn flakes processing line(the extruder) have Auto-temperature control system and self-cleaning ,which makes it more convenient.

5. The corn flakes processing line(the extruder) has the widest range of applications and can produce different products with different equipment and models.

7. About installation and after-sale service system:

a. Per-market sale of after-sale question answer for corn flakes processing line;

b. Provide detailed after-sale instruction for corn flakes processing line ;

c. Provide the in-door installation, equipment debugging, technical training service for corn flakes processing line;

d. 1 Year complete warranty and life-time maintenance service for corn flakes processing line.

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for Special Design for Energy Bar Extruder - Industrial Automatic Corn Flakes Extruder Corn flakes making Machine Price – Dongxuya , The product will supply to all over the world, such as: Detroit, Eindhoven, Auckland, We are trying our best to make more customers happy and satisfied. we sincerely hope to establish a good long-term business relationship with your esteemed company thought this opportunity,based on equal, mutual beneficial and win win business from now till the future.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.